- RFQ Mail Receipt from Customer

- Customer Investigation

- Customer Market Goodwill

- Customer Portfolio

- Customer Business Policy

- Customer Market Presence

- Customer Future Plan

- RFQ or Inquiry Potential

0+

Years of Experience

0+

Products

0+

Customers

Welcome to

Gravity Group of Companies

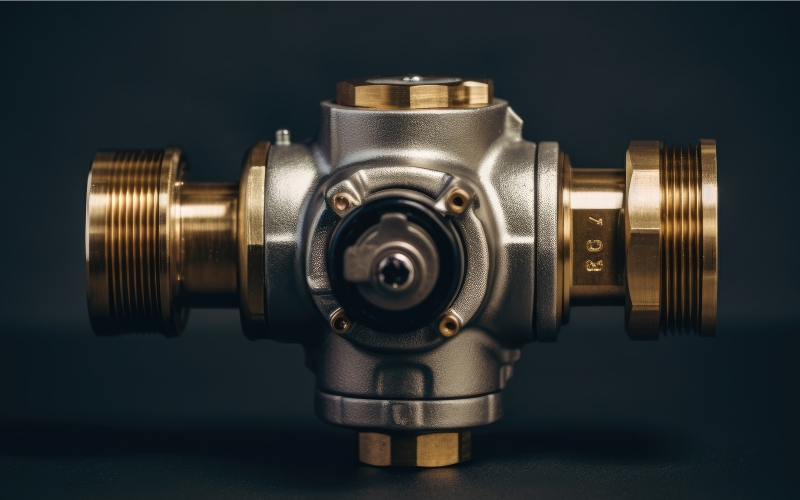

Gravity Cast Pvt. Ltd. - Gravity Group of Companies is a leading

Manufacturer & Supplier of Metal Parts like Casting, Forging and Precision

Machining Products in India.

WHO WE ARE

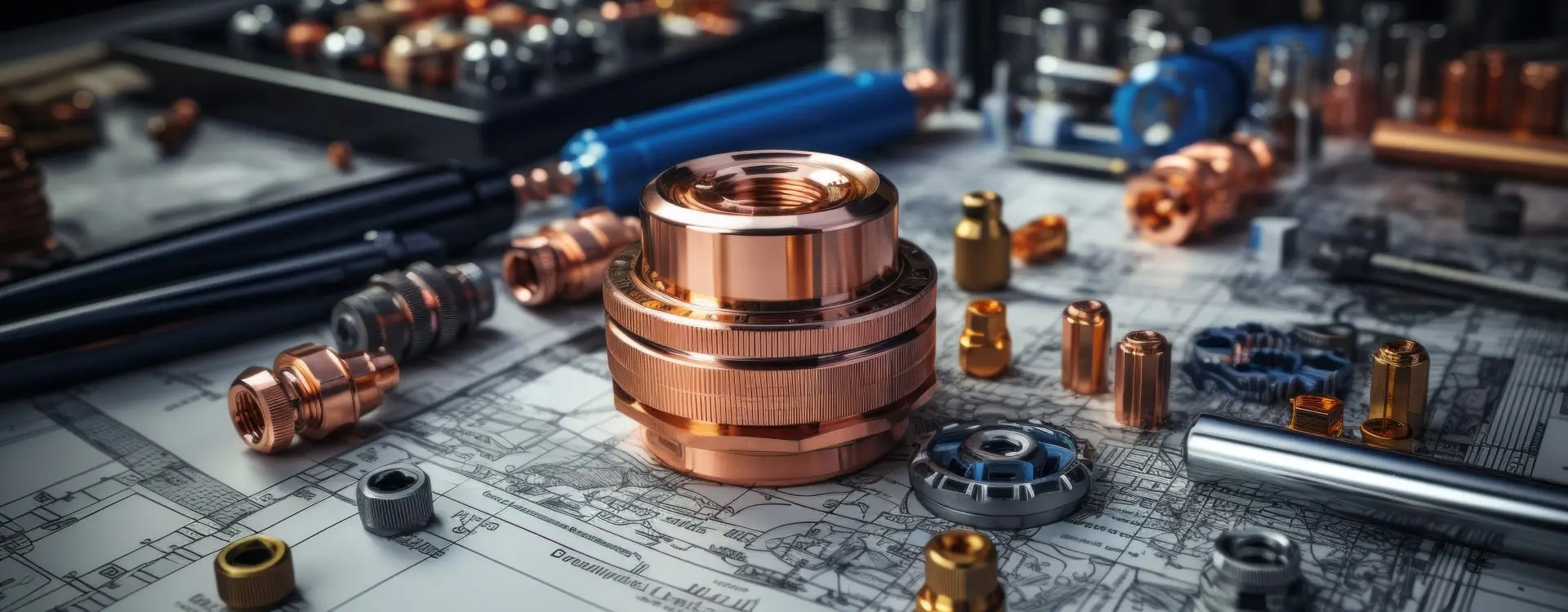

About Gravity Group of Companies

Gravity was established in 2004 manufacturing Investment

Castings (Lost Wax

Process) and Based on Customer Demand Single Window - One Stop Solution point of

view step by step our portfolio increased with other Casting,

Forging and Precision Machining methods which able to supply

components in various conditions like Raw, Finished, Assembled or as per

Customer's Demand.

Gravity Group has earned

reputation by providing Metal Parts to the various

industries according to their standard requirement and also in customized shape,

size and wide range of materials. Our experienced team are involved for

providing a superior product value, rather than just a low unit cost with

assured quality within time frame.

Single Window One Stop Solution for Metal - Plastic - Rubber Components

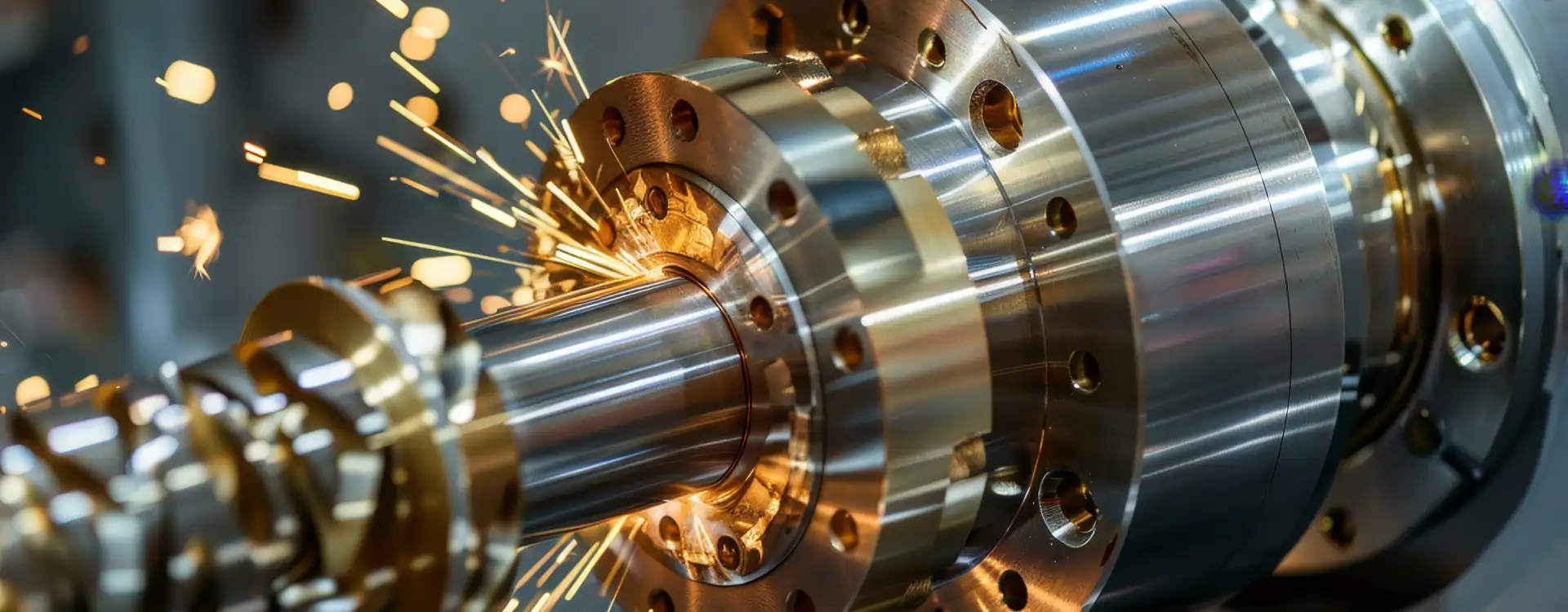

Our Technology

Perfect Solution for Metal Parts Demand

Investment Casting

Investment casting is an industrial process based on lost-wax casting, one of the oldest known metal-forming techniques. The term "lost-wax casting" can also refer to modern investment casting processes as per requirement.

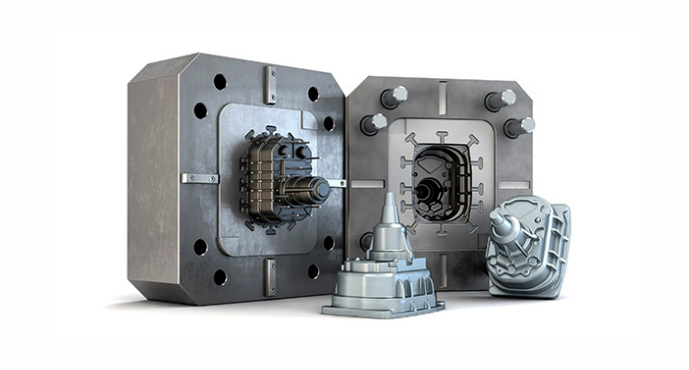

Pressure Die Casting

Pressure die casting is a process in which molten metal is forced under pressure into a securely locked metal die cavity, until the metal solidifies. After solidification of the metal, the die is unlocked, opened, and the casting ejected.

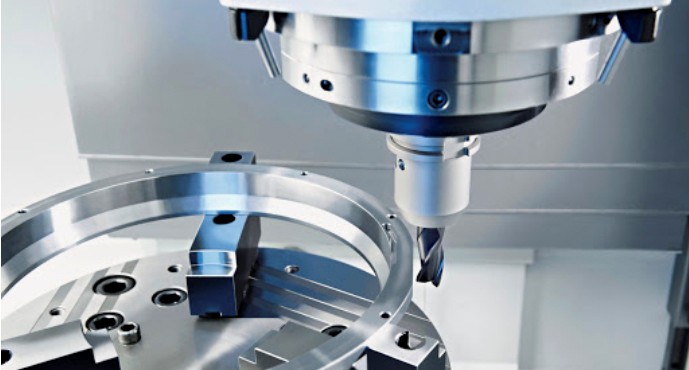

Precision Machining

Machining is a manufacturing process where a desired shape or part is created using the controlled removal of material, most often metal, from a larger piece of raw material by cutting. Machining is a form of subtractive manufacturing.

How to Proceed

The Way of Working

System

Process

- RFQ Upload in ERP System

- Technical Feasibility Review

- Technical Queries

- Technical Queries Solution

- Technical Clarification

- Cost Estimation

- Official Quotation

- Finalisation

Development

- Tooling & Sample PO

- Proforma Invoice (PI)

- Payment Receipt

- Engineering Approvals

- Tooling Development

- Sample Development

- Sample Submission

- Sample Approval

Production

- Pilot Batch PO

- Proforma Invoice (PI)

- Payment Receipt

- Pilot Batch Development

- Pilot Batch Submission

- Pilot Batch Approval

- Production PO, PI & Payment

- Serial Bulk Production

Serve to

Broad Market Segment

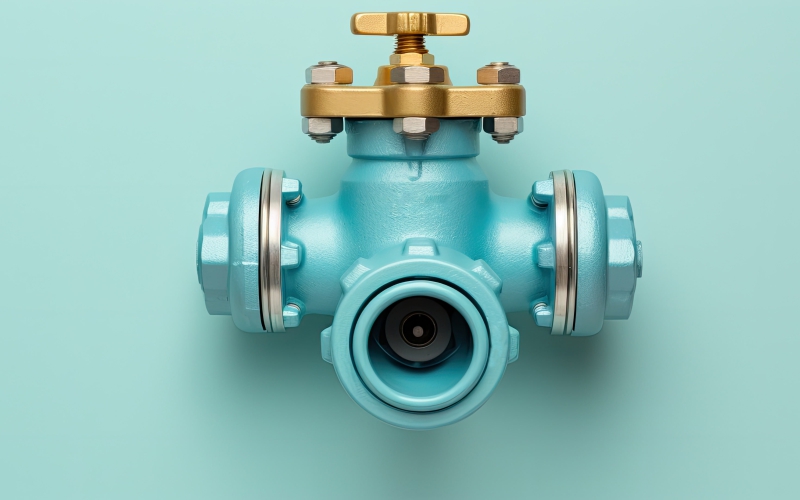

Energy

- Industrial Plant

- Water & Flow

- Motion Control

- Green Energy

- Oil & Gas

- Green Hydrogen

- Electric Vehicle

- Solar Plant & Wind Mill

Engineering

- Agriculture & Automation

- Hydraulic & Pneumatic

- Defence & Military

- Medical & Pharma

- Electrical & Electronics

- Power Tools & Appliances

- Fire Fighting & Art

- Textile & Food Processing

Infrastructure

- Mining & Road Network

- Bridge Structure

- Tunnel Passage

- Aviation Base

- Electrification

- Building Construction

- Dam Construction

- Hardware & Plumbing

Transportation

- Automotive or Automobile

- Railway & Metro

- Earth Moving

- Marine & Shipyard

- Material Handling

- Car / Bus / Truck

- Bicycle & Bike

- Motorsport Vehicles

Current Scope of

Certification Approvals

ISO 9001 : 2015

ISO 45001 : 2018

ISO 14001 : 2015

PED 2014/68/EU

AD 2000 Merkblatt W0

IBR Approved

ASNT Level 2

Third Party Inspection

Current Scope of

Supply Condition

10%

As-Raw Components

60%

Separate Finished Components

30%

Finished Sub-Assemblies

Locate in Geography

Global Supply

USA

UK

Germany

France

Spain

Israel

Italy

Russia

Singapore

United Arab Emirates

Australia

New Zealand

Netherlands

Sweden

Canada

Egypt

Thailand

Belgium

Denmark

Mexico

Peru

South Africa

South Korea

India

Contact Us

Get in Touch

Fill All your information and details for communication with us & get

details as soon as possible.

Required fill fields such as your Personal Details & Contact Details for communication about your Requirements.

Get in Quote

Required fill fields such as your Personal Details & Contact Details for communication about your Requirements.